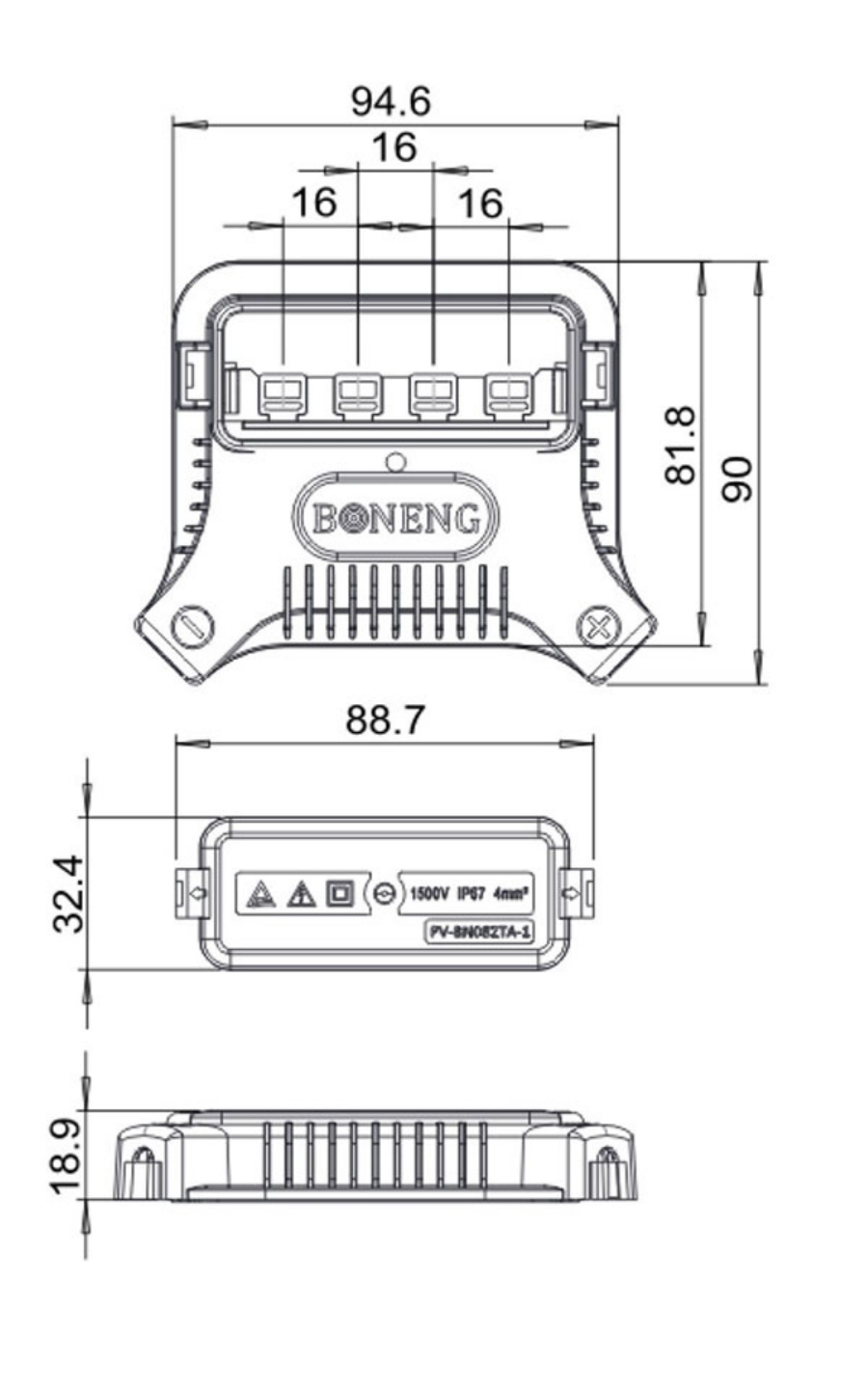

High quality and hot sale pre-potting crystal silicon junction box PV-BN082TA-1

Description

This solar junction box adopts Pre Potting-glue waterproof, the cover of junction box is waterproof by sealing ring,which simplifies the customer’s production technique.The product is certified by TUV.The junction box can reduce PV module’s power consumption and improve electrical reliability.

Technical data

| Rated voltage | 1500V | Flame Class | UL94-V0 (TUV)/5VA(UL) |

| Rated current | 15A | Cable Specifications | 4mm2 |

| Operating temperature | -40°C-+85°C(TUV)/-40°C-+90°C(UL) | Waterproof Structure | Seal ring |

| Safety class | Class II | Waterproof rating | IP67 |

| Application level | Class A | Potting Glue quantity | |

| Maximum bus bar width | 8mm | Busbar connect ion | Soldering |

| Insulation Material | PPE | Contact Material | Copper,Tin-Plated , |

Product Configuration List

| Diode Rated Voltage | 15A |

| Diode Type | SB3045 |

| Diode Qty | 3 |

Application

Unshielded solar panels for thin film batteries to improve solar energy

Solution

● PV module’s ribbon alignment must be complied with JB’s mounting hole of the terminal base.

● Adhesive and sealing compound, Potting glue must be applied by using specific type and specification. Make sure JB will be fixed in the correct position and reliable sealant. The potting glue level should be over the top surface of Diodes and terminal base. In order to avoid electrical shock risk.

● Don’t move PV module or JB before adhesive and sealing compound or potting glue solidify.

● Ensure soldering between Ribbons and terminal reliably in order to avoid missing soldering or false soldering. The soldering operators must be professionally trained. More soldering time will cause the diodes damaged.

● Adopt anti-static protection solutions when touch or solder JB.

● Make sure the connection method between JB and PV module in the correct polarity. Otherwise, Wrong connection will cause fire.

● PV module manufacturer should inspect the diodes of JBs before shipment since the diodes might be damaged by heat temperature or the static shock.

● Installation or maintenance should be operated by the professional personnel.

● For protection against electric shock, while being assembled or disassembled, make sure connectors isolated from the power supply.

● Don’t connected or disconnected under load.

● During the assembly process, keep the connector away from any corrosive materials.

Why Choose Us

As a direct manufacturer, we can provide consumers with high-quality, personalized and reasonably priced products. We enjoy a good reputation among our competitors and customers. In addition, we provide consumers with better after-sales support to meet all their needs.

Attention

1.Gently holding and releasing in transportion, no damage to product.

2.When installing the junction box, making sure the solar panel is not working and you can’t touch the plus and minus rails at the same time avoiding an electronic shock and diode disruption.

3.Do not connect the plus and the minus together of the same junction box at any time.

4.Do not insert and withdrawal the plus and minus connector frequently except repairs ecause the sealing performance will be cut down.

6.When installation, evenly smear the silica adhesive on the base of the junction box in order to prevent leakage.

7.Keep the rubber clean and no adhesive when assembly, or it affect the efficiency of the panel.

8.Keep paraffin away from PV junction box and connector, such as, oil,ubricant,electric revival,and other paraffin substance

FAQ